Reduce IG Field Failures by Monitoring the Oven Exit Temperature of Every IG Unit With ThermalSense

Monitor Adhesion Line Oven Exit Temperatures of Every Unit with Less Labor

The second most frequent reason insulating glass units fail in the field is because the adhesion line oven temperature is too low*. Too often, this goes undetected until an installed unit fails.

With ThermalSense from Integrated Automation Systems, you monitor the oven exit temperature of every unit. This allows you to immediately adjust oven speed and reheat below-limit units.

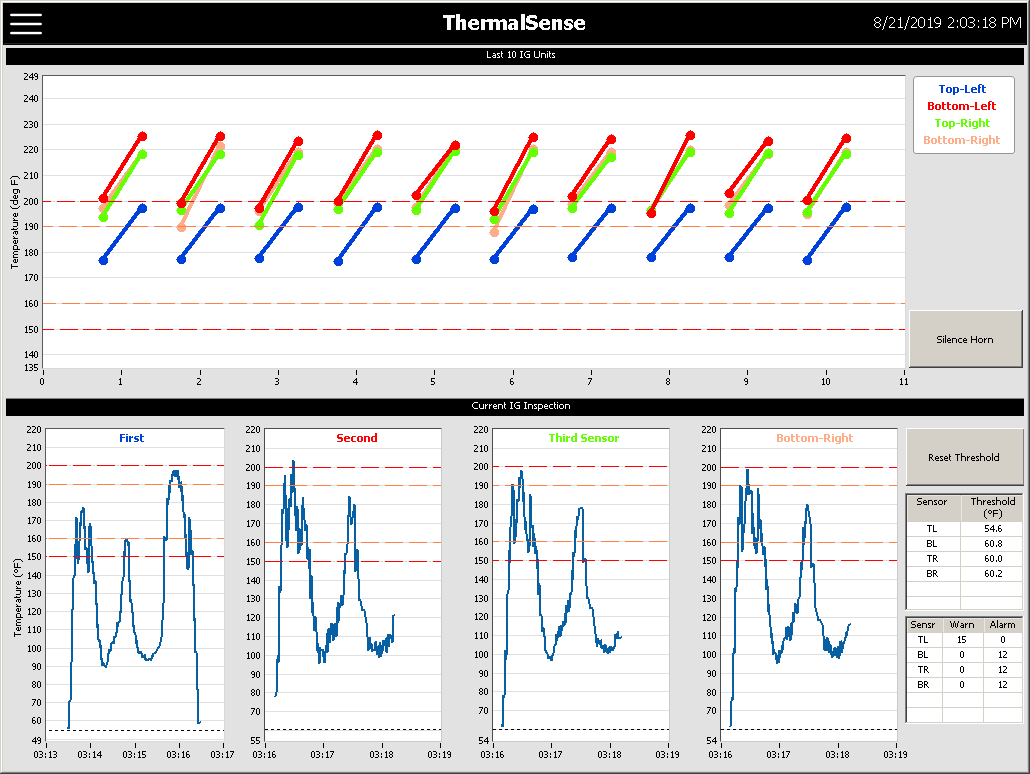

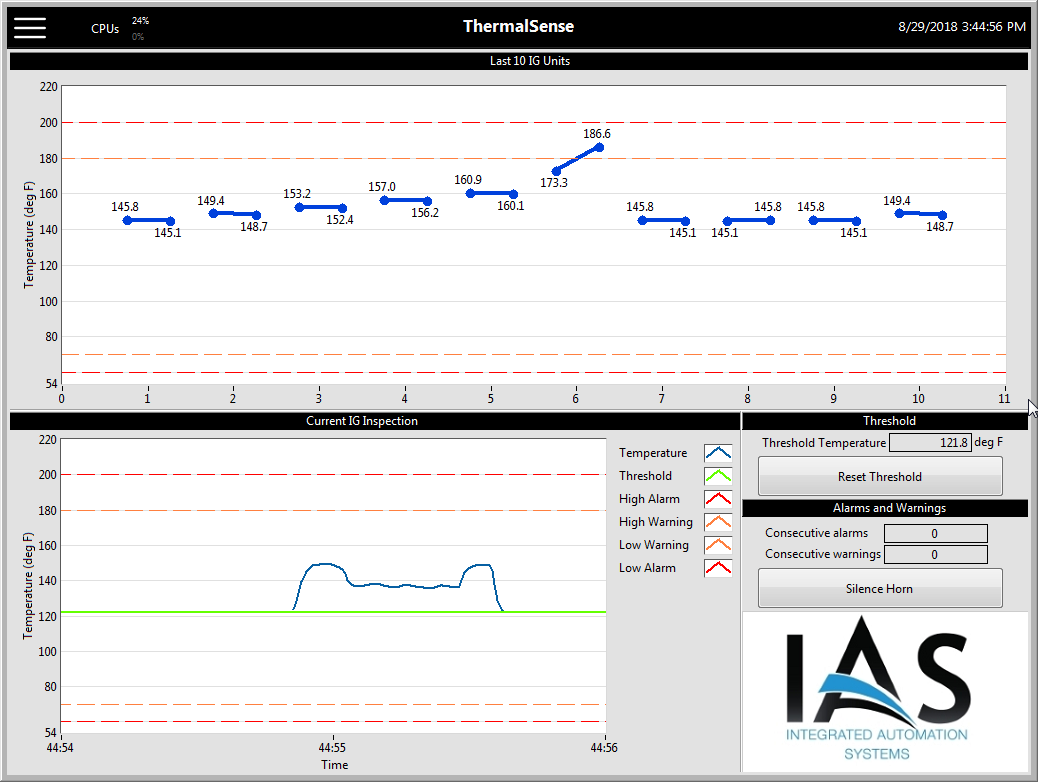

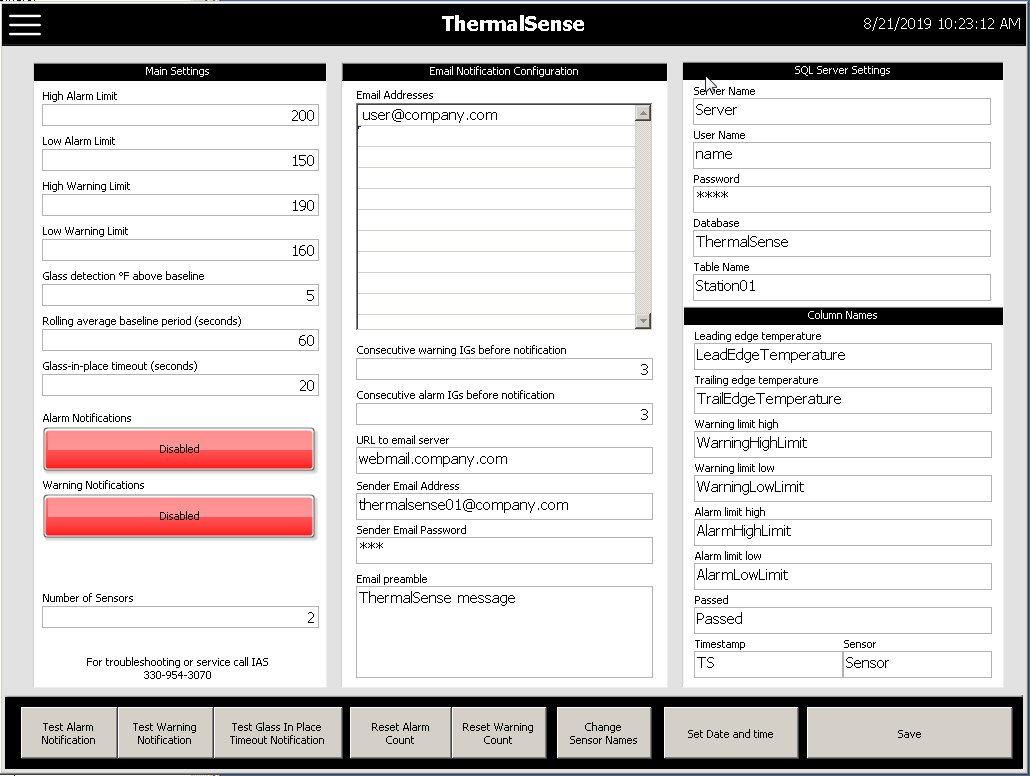

- Simply enter your upper and lower limits. The chart displays the temperature for every unit.

- Monitor up to four sensors (top, right, bottom, left).

- When a unit is outside the limits, the green light turns red.

- ThermalSense can also immediately send an email or text for any unit in warning and alarm zones.

- Operators can make real-time process adjustments.

- All data is recorded and can be reviewed for trends and issues.

Operation is Simple

You enter your upper and lower limits. The chart displays the temperature for every unit. When a unit is outside the limits, the green light changes to red. ThermalSense can also send a message at the same time. All data is recorded and can be reviewed.

ThermalSense costs less than investigating and replacing just a few units in the field. It works with Intercept® and Duralite® spacers. Future capabilities include interfacing with your oven speed control to automatically keep temperatures within the limits.

* The most common reason for IG field failures is inadequate fourth corner patching. We have a solution for that!